Black Cleanroom Safe ESD Inspection Wipers are for cleaning and final inspection of components in controlled environments.

These cleanroom-safe black wipes have been developed to clearly and visibly show small particulate contamination. Their properties make them useful for both the final wipe down and for the final inspection of any surface in a critical environment or any-where particles compromise quality or performance. Black ESD Wipers are constructed with 100% continuous filament, no-run knit polyester with laser sealed cut edges.

Cleanroom Properties of the Black Cleanroom Safe ESD Inspection Wiper

The Black Cleanroom Safe ESD Wipers are compatible with class 100-1000 cleanrooms (ISO4 - ISO6). Laser sealed edges ensure ultra -low lint and contamination and they are double bagged and vacuum packaged in cleanroom packaging.

- INSPECTION: The black color shows contamination that other color wipers do not, which ensures cleanliness after final cleaning.

- ANTISTATIC: Made out of 100% continuous polyester filaments with conductive carbon yarns that dissipative electrical charges

- CLEANROOM SAFE: The edges are laser sealed to ensure ultra-low lint and particle generation. The wipers are suitable for Class 100-1000 cleanrooms.

- GENERAL USE: Perfect for general use cleaning applications in ESD sensitive areas as well as cleaning of process tool and other equipment.

- CLEAN: Ideal for wiping exterior areas of products in ESD sensitive areas

- SIZE: The wiper is 9”x9” and packaged 150 wipers to a bag.

Why Use Black Cleanroom Safe ESD Inspection Wiper?

The purpose of wiping a surface with a cleanroom wipe is to remove contaminants including dust, dirt, oil, greases, soot, and flux. But, after wiping, how clean is the surface? How can an operator or quality inspector be sure?

Visually inspecting the wipe is the quickest and easiest way to check cleanliness. If the wipe looks dirty and the substrate looks clean, the wiping process was successful. That works well if the wipe and the contaminants are contrasting colors. Since most wipes are white, black or dark color soils are easily seen. However, many contaminants are not dark colored. Instead they are white or light colored. Since they are the same color as the wipe, visually inspecting the used wipe is not completely useful. This is especially true if the contaminant is particulate; especially small particulates.

How To Use Inspection Wipers?

The best way to use an inspection wipe is to quarter fold it. The wipe is then held in the hand with the cut edges in the palm. The thumb should hold the four corners firm in the palm while the fingers apply pressure on the wipe, just behind the folded edges. The wipe can then be refolded to expose four fresh cleaning surfaces that are untouched.

Product Attributes

Type

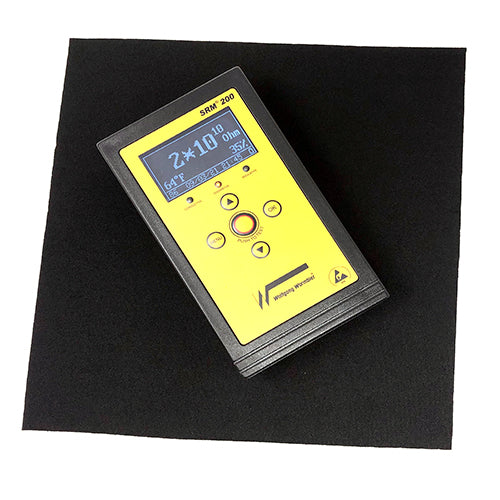

Resistance

Brand

Sku

Weight

Specifications

Standards

Surface resistance

Material

Let customers speak for us

- Choosing a selection results in a full page refresh.